上一頁下一頁

將軍寇DM

將軍寇底圖

姑娘一十八

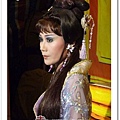

《鴛鴦遺恨》劇照

民國九十年,春美姊於高雄外台歌仔戲匯演,演出《飛賊黑鷹》。

春美姊 六、七歲時

我最愛的笑容

春美歌劇團首頁

是不是很有女人味

2009年生日 1531631036

F23_20091124102729435

100206

20130101 黃郁晴FB 跨年晚會 歌仔戲紅白大對抗 台北大稻埕戲苑 46387

20130101 黃郁晴FB 跨年晚會 歌仔戲紅白大對抗 台北大稻埕戲苑 148571

20130101 黃郁晴FB 跨年晚會 歌仔戲紅白大對抗 台北大稻埕戲苑 407936

20130101 黃郁晴FB 跨年晚會 歌仔戲紅白大對抗 台北大稻埕戲苑 734131

20130101 黃郁晴FB 跨年晚會 歌仔戲紅白大對抗 台北大稻埕戲苑 207791

20130101 這些人妖受 跨年驚High反串 - 春美歌劇團【夜王子】 - 無名小站 1434343587

20130611 春美歌劇團FB 愛情的書僮 邀請照

19990714 河洛歌仔戲團錄製 - 數位典藏與數位學習聯合目錄 河洛歌仔戲團錄製「河洛歌仔戲精緻唱腔選輯 」發行記者會,由團內五大生旦示範演唱 小咪、許亞芬、劉鐘元、王金櫻、郭春美、白燕萍 19990714 河洛歌仔戲團錄製 - 數位典藏與數位學習聯合目錄 河洛歌仔戲團錄製「河洛歌仔戲精緻唱腔選輯 」發行記者會,由團內五大生旦示範演唱 小咪、許亞芬、劉鐘元、王金櫻、郭春美、白燕萍

20130611 碧月小照--林美照粉絲團 2001年3月25日《秦淮煙雨》亞太會館簽名會

20081226 秀娘逢春美麗誘惑 - 春美歌劇團【將軍寇】 - 無名小站 1143675402

20081226 秀娘逢春美麗誘惑 - 春美歌劇團【將軍寇】 - 無名小站 1143675405

20081226 秀娘逢春美麗誘惑 - 春美歌劇團【將軍寇】 - 無名小站 1143675407

20081226 秀娘逢春美麗誘惑 - 春美歌劇團【將軍寇】 - 無名小站 1143675416

20081226 秀娘逢春美麗誘惑 - 春美歌劇團【將軍寇】 - 無名小站 1143675417

20081226 秀娘逢春美麗誘惑 - 春美歌劇團【將軍寇】 - 無名小站 1143675419

20130915 郭春美FB 又搞定了愛情的書童了!雖然很累(還在復原精神中)但是心裡是開心的!有朋友跟我說~這是一觸能讓大家抒解壓力的好戲!她看完了後~連做夢也在笑~其實製作這觸戲……是非常冒險!因為跟以往的唐伯虎不相同!一定也會有人不能接受~總之~不管什麼戲……我會很努力去詮釋~讓妳們喜歡!看得到我們的用心!最大的原因是要妳們開心^~^

20131004 高雄市鳳山區衛武營戶外園區 夜王子 與母親

20131031 春美寶貝家族照片

美極了

20140303pm11:59 前 這樣有女人味嗎~哈哈哈…_meitu_2

上一頁下一頁

相片最新留言

此相簿內的相片出現在:

相簿列表資訊

- 最新上傳:

- 2014/03/05

- 全站分類:

- 不設分類

- 本日人氣:

- 0

- 累積人氣:

- 832

常見的半導體材料有矽、鍺、砷化鎵等

/

晶片測試

晶片處理高度有序化的本質增加了對不同處理步驟之間度量方法的需求。晶片測試度量裝置被用於檢驗晶片仍然完好且沒有被前面的處理步驟損壞。如果If the number of dies—the 積體電路s that will eventually become chips—當一塊晶片測量失敗次數超過一個預先設定的閾值時,晶片將被廢棄而非繼續後續的處理製程。

/

晶片測試

晶片處理高度有序化的本質增加了對不同處理步驟之間度量方法的需求。晶片測試度量裝置被用於檢驗晶片仍然完好且沒有被前面的處理步驟損壞。如果If the number of dies—the 積體電路s that will eventually become chips—當一塊晶片測量失敗次數超過一個預先設定的閾值時,晶片將被廢棄而非繼續後續的處理製程。

/

步驟列表

晶片處理

濕洗

平版照相術

光刻Litho

離子移植IMP

蝕刻(干法蝕刻、濕法蝕刻、電漿蝕刻)

熱處理

快速熱退火Annel

熔爐退火

熱氧化

化學氣相沉積 (CVD)

物理氣相沉積 (PVD)

分子束磊晶 (MBE)

電化學沉積 (ECD),見電鍍

化學機械平坦化 (CMP)

IC Assembly and Testing 封裝測試

Wafer Testing 晶片測試

Visual Inspection外觀檢測

Wafer Probing電性測試

FrontEnd 封裝前段

Wafer BackGrinding 晶背研磨

Wafer Mount晶圓附膜

Wafer Sawing晶圓切割

Die attachment上片覆晶

Wire bonding焊線

BackEnd 封裝後段

Molding模壓

Post Mold Cure後固化

De-Junk 去節

Plating 電鍍

Marking 列印

Trimform 成形

Lead Scan 檢腳

Final Test 終測

Electrical Test電性測試

Visual Inspection光學測試

Baking 烘烤

/

有害材料標誌

許多有毒材料在製造過程中被使用。這些包括:

有毒元素摻雜物比如砷、硼、銻和磷

有毒化合物比如砷化三氫、磷化氫和矽烷

易反應液體、例如過氧化氫、發煙硝酸、硫酸以及氫氟酸

工人直接暴露在這些有毒物質下是致命的。通常IC製造業高度自動化能幫助降低暴露於這一類物品的風險。

/

Device yield

Device yield or die yield is the number of working chips or dies on a wafer, given in percentage since the number of chips on a wafer (Die per wafer, DPW) can vary depending on the chips' size and the wafer's diameter. Yield degradation is a reduction in yield, which historically was mainly caused by dust particles, however since the 1990s, yield degradation is mainly caused by process variation, the process itself and by the tools used in chip manufacturing, although dust still remains a problem in many older fabs. Dust particles have an increasing effect on yield as feature sizes are shrunk with newer processes. Automation and the use of mini environments inside of production equipment, FOUPs and SMIFs have enabled a reduction in defects caused by dust particles. Device yield must be kept high to reduce the selling price of the working chips since working chips have to pay for those chips that failed, and to reduce the cost of wafer processing. Yield can also be affected by the design and operation of the fab.

Tight control over contaminants and the production process are necessary to increase yield. Contaminants may be chemical contaminants or be dust particles. "Killer defects" are those caused by dust particles that cause complete failure of the device (such as a transistor). There are also harmless defects. A particle needs to be 1/5 the size of a feature to cause a killer defect. So if a feature is 100 nm across, a particle only needs to be 20 nm across to cause a killer defect. Electrostatic electricity can also affect yield adversely. Chemical contaminants or impurities include heavy metals such as Iron, Copper, Nickel, Zinc, Chromium, Gold, Mercury and Silver, alkali metals such as Sodium, Potassium and Lithium, and elements such as Aluminum, Magnesium, Calcium, Chlorine, Sulfur, Carbon, and Fluorine. It is important for those elements to not remain in contact with the silicon, as they could reduce yield. Chemical mixtures may be used to remove those elements from the silicon; different mixtures are effective against different elements.

Several models are used to estimate yield. Those are Murphy's model, Poisson's model, the binomial model, Moore's model and Seeds' model. There is no universal model; a model has to be chosen based on actual yield distribution (the location of defective chips) For example, Murphy's model assumes that yield loss occurs more at the edges of the wafer (non-working chips are concentrated on the edges of the wafer), Poisson's model assumes that defective dies are spread relatively evenly across the wafer, and Seeds's model assumes that defective dies are clustered together.[25]

Smaller dies cost less to produce (since more fit on a wafer, and wafers are processed and priced as a whole), and can help achieve higher yields since smaller dies have a lower chance of having a defect. However, smaller dies require smaller features to achieve the same functions of larger dies or surpass them, and smaller features require reduced process variation and increased purity (reduced contamination) to maintain high yields. Metrology tools are used to inspect the wafers during the production process and predict yield, so wafers predicted to have too many defects may be scrapped to save on processing costs.[26]

常見的半導體材料有矽、鍺、砷化鎵等

/

晶片測試

晶片處理高度有序化的本質增加了對不同處理步驟之間度量方法的需求。晶片測試度量裝置被用於檢驗晶片仍然完好且沒有被前面的處理步驟損壞。如果If the number of dies—the 積體電路s that will eventually become chips—當一塊晶片測量失敗次數超過一個預先設定的閾值時,晶片將被廢棄而非繼續後續的處理製程。

/

晶片測試

晶片處理高度有序化的本質增加了對不同處理步驟之間度量方法的需求。晶片測試度量裝置被用於檢驗晶片仍然完好且沒有被前面的處理步驟損壞。如果If the number of dies—the 積體電路s that will eventually become chips—當一塊晶片測量失敗次數超過一個預先設定的閾值時,晶片將被廢棄而非繼續後續的處理製程。

/

步驟列表

晶片處理

濕洗

平版照相術

光刻Litho

離子移植IMP

蝕刻(干法蝕刻、濕法蝕刻、電漿蝕刻)

熱處理

快速熱退火Annel

熔爐退火

熱氧化

化學氣相沉積 (CVD)

物理氣相沉積 (PVD)

分子束磊晶 (MBE)

電化學沉積 (ECD),見電鍍

化學機械平坦化 (CMP)

IC Assembly and Testing 封裝測試

Wafer Testing 晶片測試

Visual Inspection外觀檢測

Wafer Probing電性測試

FrontEnd 封裝前段

Wafer BackGrinding 晶背研磨

Wafer Mount晶圓附膜

Wafer Sawing晶圓切割

Die attachment上片覆晶

Wire bonding焊線

BackEnd 封裝後段

Molding模壓

Post Mold Cure後固化

De-Junk 去節

Plating 電鍍

Marking 列印

Trimform 成形

Lead Scan 檢腳

Final Test 終測

Electrical Test電性測試

Visual Inspection光學測試

Baking 烘烤

/

有害材料標誌

許多有毒材料在製造過程中被使用。這些包括:

有毒元素摻雜物比如砷、硼、銻和磷

有毒化合物比如砷化三氫、磷化氫和矽烷

易反應液體、例如過氧化氫、發煙硝酸、硫酸以及氫氟酸

工人直接暴露在這些有毒物質下是致命的。通常IC製造業高度自動化能幫助降低暴露於這一類物品的風險。

/

Device yield

Device yield or die yield is the number of working chips or dies on a wafer, given in percentage since the number of chips on a wafer (Die per wafer, DPW) can vary depending on the chips' size and the wafer's diameter. Yield degradation is a reduction in yield, which historically was mainly caused by dust particles, however since the 1990s, yield degradation is mainly caused by process variation, the process itself and by the tools used in chip manufacturing, although dust still remains a problem in many older fabs. Dust particles have an increasing effect on yield as feature sizes are shrunk with newer processes. Automation and the use of mini environments inside of production equipment, FOUPs and SMIFs have enabled a reduction in defects caused by dust particles. Device yield must be kept high to reduce the selling price of the working chips since working chips have to pay for those chips that failed, and to reduce the cost of wafer processing. Yield can also be affected by the design and operation of the fab.

Tight control over contaminants and the production process are necessary to increase yield. Contaminants may be chemical contaminants or be dust particles. "Killer defects" are those caused by dust particles that cause complete failure of the device (such as a transistor). There are also harmless defects. A particle needs to be 1/5 the size of a feature to cause a killer defect. So if a feature is 100 nm across, a particle only needs to be 20 nm across to cause a killer defect. Electrostatic electricity can also affect yield adversely. Chemical contaminants or impurities include heavy metals such as Iron, Copper, Nickel, Zinc, Chromium, Gold, Mercury and Silver, alkali metals such as Sodium, Potassium and Lithium, and elements such as Aluminum, Magnesium, Calcium, Chlorine, Sulfur, Carbon, and Fluorine. It is important for those elements to not remain in contact with the silicon, as they could reduce yield. Chemical mixtures may be used to remove those elements from the silicon; different mixtures are effective against different elements.

Several models are used to estimate yield. Those are Murphy's model, Poisson's model, the binomial model, Moore's model and Seeds' model. There is no universal model; a model has to be chosen based on actual yield distribution (the location of defective chips) For example, Murphy's model assumes that yield loss occurs more at the edges of the wafer (non-working chips are concentrated on the edges of the wafer), Poisson's model assumes that defective dies are spread relatively evenly across the wafer, and Seeds's model assumes that defective dies are clustered together.[25]

Smaller dies cost less to produce (since more fit on a wafer, and wafers are processed and priced as a whole), and can help achieve higher yields since smaller dies have a lower chance of having a defect. However, smaller dies require smaller features to achieve the same functions of larger dies or surpass them, and smaller features require reduced process variation and increased purity (reduced contamination) to maintain high yields. Metrology tools are used to inspect the wafers during the production process and predict yield, so wafers predicted to have too many defects may be scrapped to save on processing costs.[26]